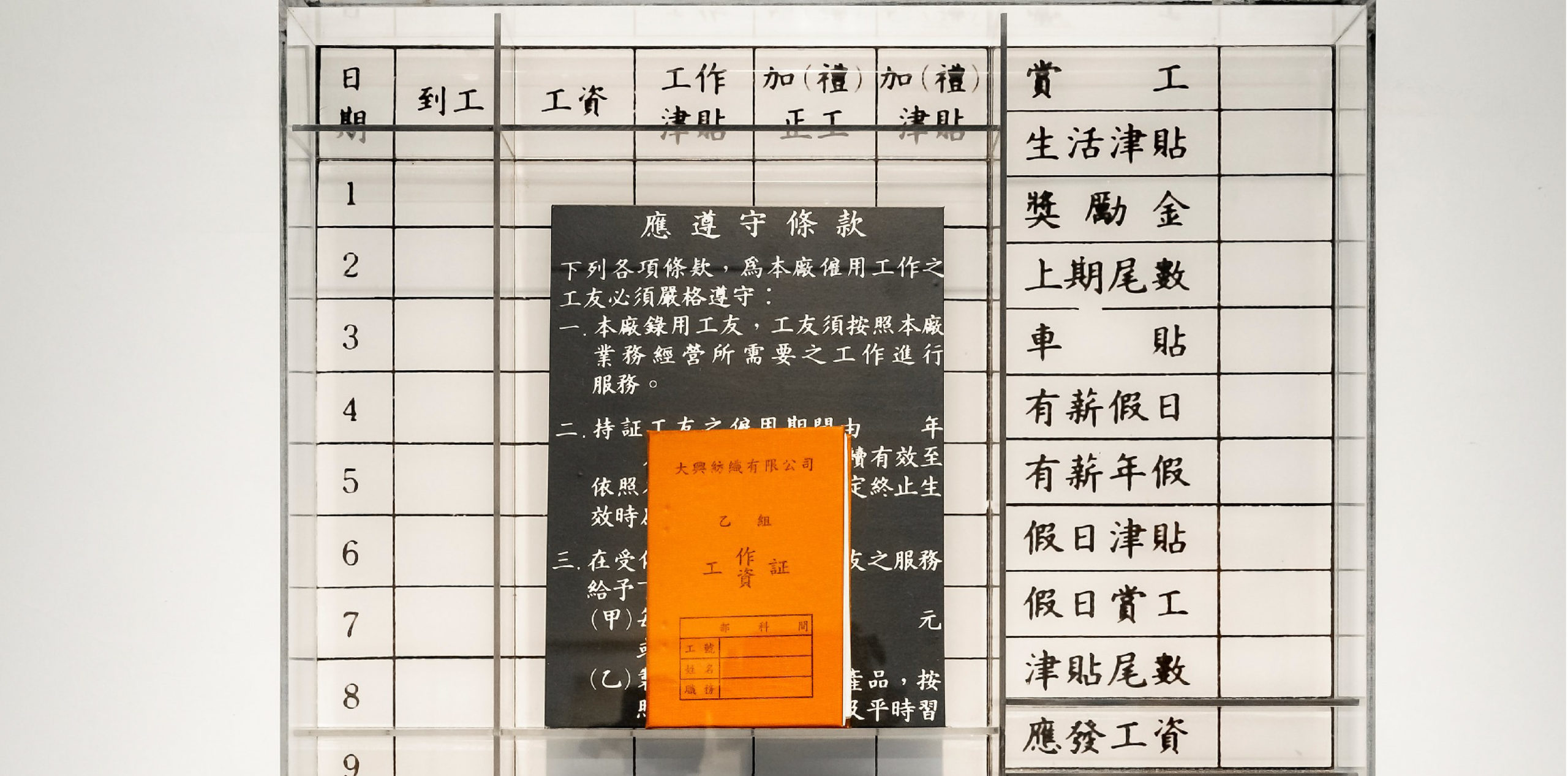

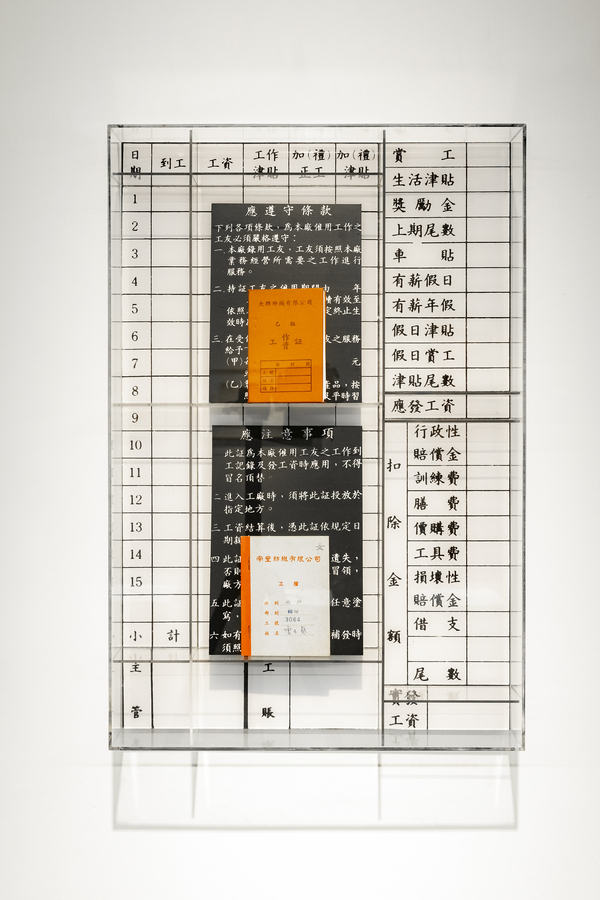

Worker attendance and salary record from the 1970s-80s

Spinning Mill Intern Handbook (Part 2)

25.02.2022

CHAT tells the story of textile through voices spanning generations, industries and disciplines. Here at CHAT, we invite different stakeholders to respond to and activate the stories from our Memory Bank based on interviews with former factory workers. In this article, CHAT’s 2021 intern Pat Cheung brings to life the story of Chan King Keung, a former textile mill foreman.

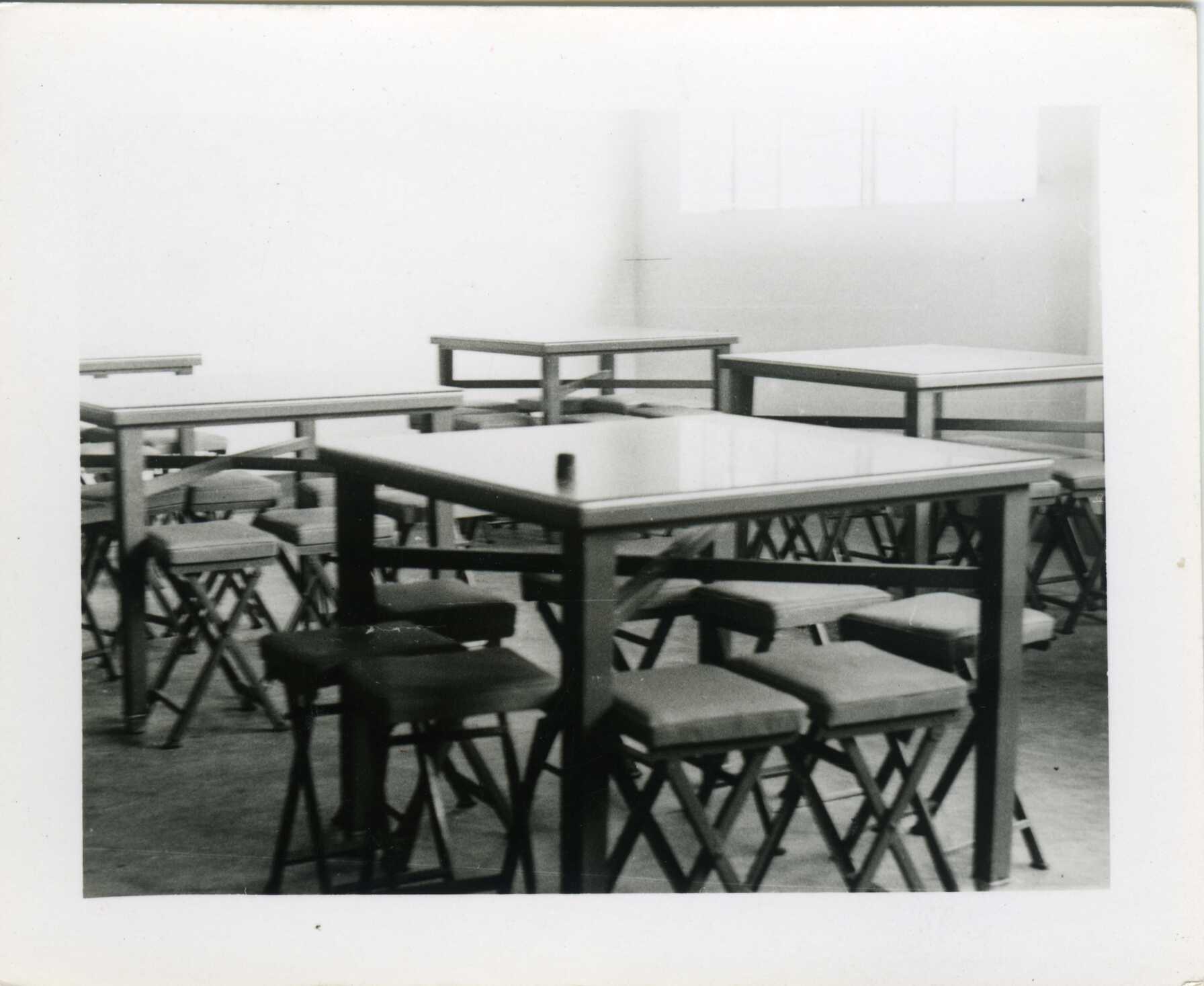

Staff canteen at Nan Fung Textiles Mill 1, not far from Oceanic Cotton Mill on Castle Peak Road

Staff canteen at Nan Fung Textiles Mill 1, not far from Oceanic Cotton Mill on Castle Peak Road

A Day in the Life of an Intern

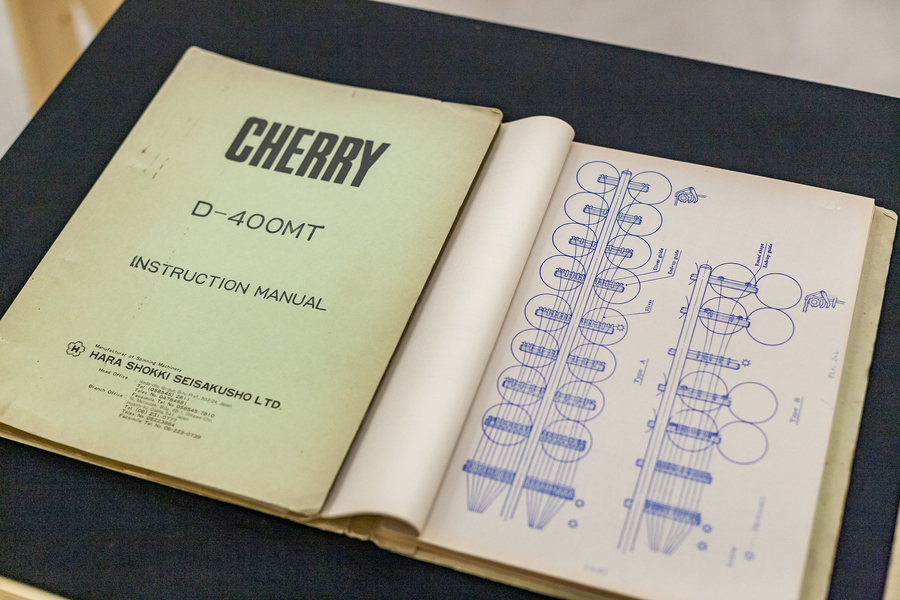

Oceanic Cotton Mill offered accommodation for the interns. One unit accommodated 6 workers, and a woman cleaner was typically on-site to take care of the chores. And just like that, Mr Chan began his co-living days with the other 5 interns. Routine was key in their everyday lives. Lectures and training took place every morning, afternoon and evening, interspersed with three meals provided at the staff canteen. Every morning, interns would go to the factory floor to observe the cotton mill and the different machines in operation. Meanwhile, theoretical knowledge concerning various department at the mill would be taught by different teachers in the afternoons and evenings. From production in the Spinning Division to maintenance, mechanical drawing, weaving, and even accounting and human resources management, the interns were to familiarise themselves with every aspect of the cotton mill.

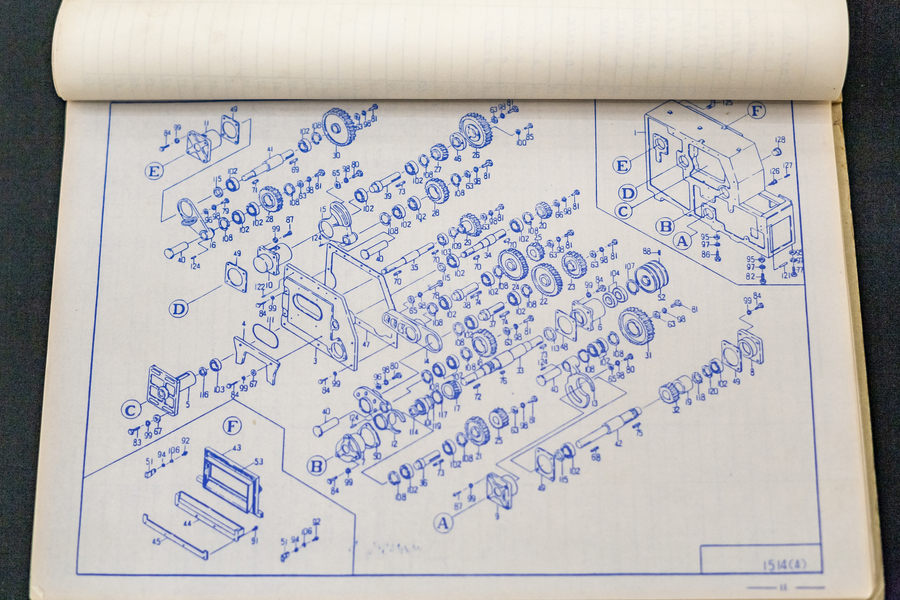

Cherry draw frame parts catalogue

Cherry draw frame parts catalogue

Throughout the week, the interns were required to stay at the mills for 5 and a half days. Apart from their personal free time in the dormitories during the week, they could only leave the factory to attend Physical Education lessons for exercise in the form of basketball or tennis in the evenings. Weekends were, therefore, a precious time for relaxation amidst such a packed schedule. Every Saturday afternoon, the factory would arrange a shuttle bus to send everyone home and then bring them back the next day. If someone missed the shuttle, they would have to find a way back to the factory by the 10:30pm curfew on their own.

These were no easy terms and conditions. What was the motivation for undergoing and committing to a two-year training in such a high-pressure environment? ‘The salary is an attraction certainly,’ said Mr Chan.

The Best Job in Hong Kong

After training for a year and a half, Mr Chan and his fellow interns, who had yet to graduate from secondary school nor to choose their field of study, were sent to the factory to begin overseeing production. After they had graduated, his salary was raised from HK$200 to HK$1,650 – more than double the average wage on the labour market. Their competitive benefits scheme also included meal and housing subsidies with 13th-month payments and bonuses equivalent to 4 to 6 months of salary. Graduates like them only had to work for a year or so to have the means to purchase a flat in Tsuen Wan. It is no wonder that they were committed to the internship programme, and eventually graduated from it.

Worker attendance and salary record from the 1970s-80s

Worker attendance and salary record from the 1970s-80s

After officially becoming a foreman in the Operations Department, Mr Chan was responsible for managing a new factory floor and its entire production line, from blowing to open-end spinning. The cotton mill ran 24/7 in its heyday, during which the foreman and Division manager would work round the clock in three shifts. The morning shift usually had more extended hours, while arrangements for the afternoon and night shifts were flexibly interchangeable.

Hong Kong: Remembered

According to Mr Chan, there had only been three cohorts of interns at Oceanic Cotton Mill. Looking back at his internship years, he would never forget the many teachings of his mentors and the way they inspired him. ‘I looked to Mr Cheung Yuen Lung for all things operational, Mr Lau Kam Sing for maintenance expertise, Mr Yu Yuk Lung for research and development, and Mr Lam Yuen Leung from Wheelock for knitting and weaving.’ Mr Chan is also grateful for his fellow colleagues and workers, whose company and support motivated him to tackle the difficulties at work.

Upon leaving Oceanic Cotton Mill, Mr Chan first worked at Ying Cheong Textiles in Ping Shan, before returning to Tsuen Wan to work at Texas Cotton Mills on Texaco Road. As local textile companies moved their production up north and to other parts of the world in the 1980s, he, too, shifted his career to the plastic manufacturing industry, after 10 years of working in textiles.

Decades have come to pass since Mr Chan left the textile industry. But in a way, Tsuen Wan has never left him. He remains in the district in Allway Gardens, where he lives with his wife. Above and beyond the salary and benefits of the job, his internship and work experience left him with precious memories of the industry’s golden age, his community and people he worked with. Having accomplished its role in the development of Hong Kong’s economy, the textile industry has since retired from its toil and settled into its place in history. As time passes and history turns its pages, may we keep alive in our memories these anonymous heroes who has helped make Hong Kong as it is today.

Read Part 1 here.

If you or anyone you know has worked in the textile industry and would be willing to share your stories, we would love to hear from you. Please get in touch by emailing enquiry@mill6chat.org with the subject line ‘CHAT Memory Bank’ or call +852 3108 2399.